With the electrification of motorsport growing, an ambitious team of dedicated University of Warwick students has committed to producing a highly innovative electric superbike. The case study is prepared in collaboration with the Press, Partnership and Sponsorship team at Warwick Moto.

英国

Electric superbike structural subframe for high-performance racing

Warwick Moto started in mid-2019 with the aim to compete in the electric class of the prestigious Isle of Man TT (IoM) and many other competitive international races. An interdisciplinary team of 25 students and academics are working at the forefront of electric motorsport innovation to achieve this ambitious goal. Although racing is a primary target, Warwick Moto also provides a platform through which young engineers can find their feet in a more industrial environment. With this comes another aim of upskilling University of Warwick engineers and exposing them to real world engineering.

Their motorcycle, ‘Aurora’, is designed around a superbike chassis known for its excellent handling. The team are developing state-of-the-art electrical systems to be implemented in their race motorcycle, using innovative solutions such as an immersion cooled battery pack and original subframe designs featured in this article. They have also signed a seasoned superbike racer, Tom Weeden to ride for the team.

The unique and ambitious innovations of the students coupled with support from sponsors, have enabled the project to push forward even during the unprecedented times of the global pandemic. Find out more about Aurora and its progress here.

The Subframe Build

The process of converting a traditional internal combustion engine into a modern electric vehicle is no easy task, and several engineering challenges surrounding the packaging of componentry arose. It soon became apparent that the superbike’s original subframe (the area in which the rider’s seat is situated), required a redesign to facilitate an electric inverter; a design choice driven by packaging constraints. This was made even more challenging due to COVID-19 limitations which restricted the team’s access to the engineering facilities available at WMG, University of Warwick. Consequently, Warwick Moto enlisted the support of on-demand component manufacturer Xometry, who provided the manufacturing capability, technical expertise and materials to achieve the subframes complex requirements.

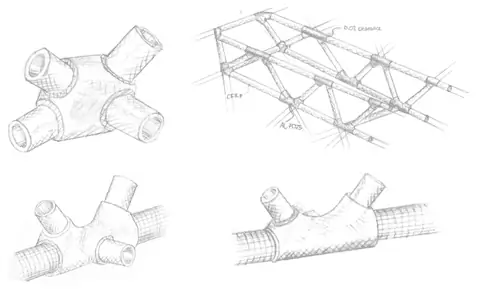

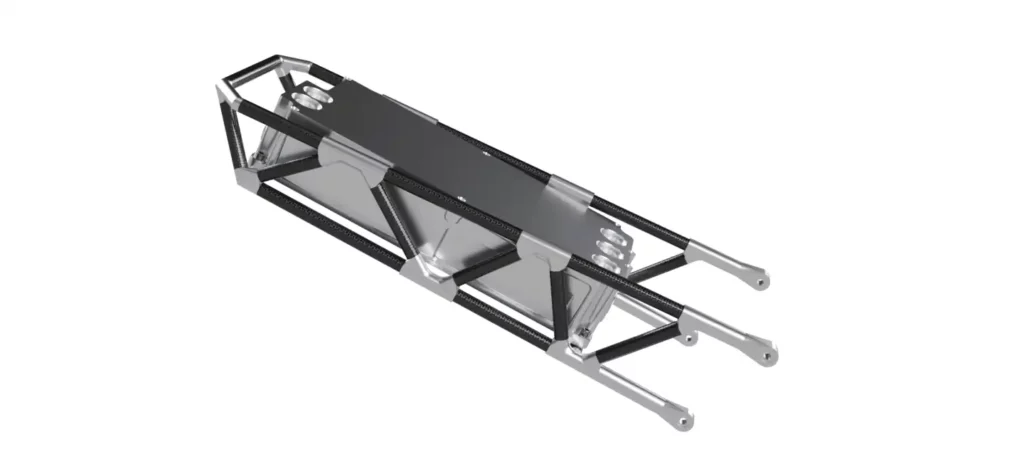

From design concepts through to manufacturing, the team worked relentlessly on the subframe project. Two first year engineering students Nesta Ferguson and Aneesh Jois spearheaded the design process in consultation with the rest of the student team and academic supervisors through the use of Microsoft Teams. More than 100 design iterations were developed over a six-month period, optimising the design at each stage while also refining the team’s CAD skills. The culmination of this was the creation of an industry-first carbon tube, aluminium node subframe which houses an inverter whilst also maintaining a competitive racing weight. This resulted in an unique 1.3kg subframe, approximately 1.5kg less than the standard off-the-shelf product.

The Design Brief

The design cycle of the subframe primarily involved conceptualising designs to fit constraints, then iterating and validating these concepts through Finite Element Analysis (FEA). A key challenge of the process was understanding the manufacturing tolerances required to maintain a minimum bond gap at the tube-node interfaces across each joint. This was paramount to the effective assembly and structural integrity of the part.

Rock West Composites aided the students throughout their design process, helping with carbon fiber tube selection, bonding requirements and material capabilities. FEA analysis was conducted extensively throughout the design process to identify weak points which were improved upon in each iteration. This analysis involved developing a variety of load cases to simulate extreme racing conditions, all whilst also optimising the subframes structure with the team using generative design methods to minimise overall mass.

With all parts now in the Warwick Moto workshop, they look to assemble and complete the physical subframe in the near future. The development of the final design itself would not have been possible without Xometry’s technical input into the manufacturing feasibility of the nodes, and Rock West Composites knowledge of carbon development and assembly.

Xometry’s leading manufacturing capabilities, including precision 5-axis machining, ensured that this major innovation in subframe design was realised to its full potential. Moreover, this unique opportunity gave the students invaluable experiences that built on their understanding of manufacturing constraints, design cycle optimisation, and failure analysis.

Logistical and Technical Challenges

Throughout this project, the Warwick Moto team faced many logistical and technical challenges due to the coronavirus pandemic’s unprecedented circumstances. Although coronavirus put many plans on hold, the team is successfully moving forward with designing and manufacturing the electric superbike from home with all communication being conducted virtually. Through countless hours of Microsoft Teams calls, the team redesigned this vital structural component. On hand technical support was provided virtually by Xometry and was key to the success of this product. With the extensive periods of working from home Warwick Moto as an organization embraced virtual workflow, not only conducting meetings but also using the platform to interact and socialize with one another. The aim being to maintain good health and morale of everyone through the difficult times.

What’s Next?

The team wrapped up 2020 by successfully finishing most of the design work required for the bike with only smaller parts remaining. Their objective going into 2021 is to begin manufacturing and assembly of all their components to put the bike on track in the coming months (in line with Covid-19 guidelines). With the knowledge gained from experiences such as the Subframe project more components are being designed and simulated at this very moment. Xometry are supporting the team further in regards to their immersion cooled battery packs and continual work is being done with other industrial partners to ensure the success of Warwick Moto’s first generation superbike.

If you are interested in finding out more about the Warwick Moto team’s progress find them at:

- Website: https://warwick.ac.uk/fac/sci/wmg/education/undergraduate/student-projects/warwick-moto/

- Facebook: https://www.facebook.com/warwickmotoracing/

- Instagram: https://www.instagram.com/warwick.moto/

- LinkedIn: https://www.linkedin.com/company/warwick-moto/

The team is also glad to be supported by WMG centre High Value Manufacturing Catapult, Michelin Tyre PLC, MIVOLT Liquid Immersion Cooling by M&I Materials, Xometry, DYMAG Performance Wheels, Rock West Composites, Pro-Bolt, RS Components, Embed and Renthal.

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط