Xometry spoke to George Psarras, Electronics Design Engineer, about T4i Engineering’s advancement in the chemical instrumentation industry and the creation of a handy device to calibrate chemical detection systems inside and outside the lab using 3D printing and CNC machining.

Ujedinjeno Kraljevstvo

PA 12 (for 3D printed casing), Aluminium 6061, Stainless steel 316L (CNC machined components)

Blue dye finishing on 3D printed parts

Portable calibrator for chemical sensors (T4i FemtoMachine® PRO)

We didn’t expect the case to be a key feature of the device, but the customers thought otherwise. It was a real innovation in terms of design…

T4i Engineering Ltd was founded in 2014 as a start-up and started operating at the Advanced Technology Innovation Centre of Loughborough University (UK). Since then, it has been providing solutions and services in the areas of chemical detection, specialised electronic design and materials science. In 2019, the company also commenced operations in Lavrio (Greece).

T4i Engineering Ltd first specialised in designing modular, miniaturised and adaptive chemical detectors, but quickly realised there was a gap on the market: a portable and reasonably priced calibrator for these detectors that could easily be used on-site.

Creating a New Device to Meet Market Requirements

One key factor stood behind this innovation—the fact that a chemical detector has to be recalibrated regularly to ensure it provides accurate results. However, the calibration and recalibration process had always been tricky, as calibrators already on the market were benchtop models and meant to be used exclusively within the confinements of a lab.

The engineering team at T4i worked on the different iterations of the prototype until they came up with the T4i FemtoMachine® DEMO. This was the very first portable device with a size equivalent to an A4 sheet of paper.

When the team first presented this instrument to a customer, they immediately expressed an interest in buying the device. Once Psarras and his team had verified the performance of the first prototype, they worked on a new iteration, the T4i FemtoMachine® PRO.

Production then started scaling up after they received CE marking certification. Today, T4i counts the University of New Mexico (US) and the University of Helsinki (FI) among its diverse customers.

How Does the T4i Femtomachine® PRO Work?

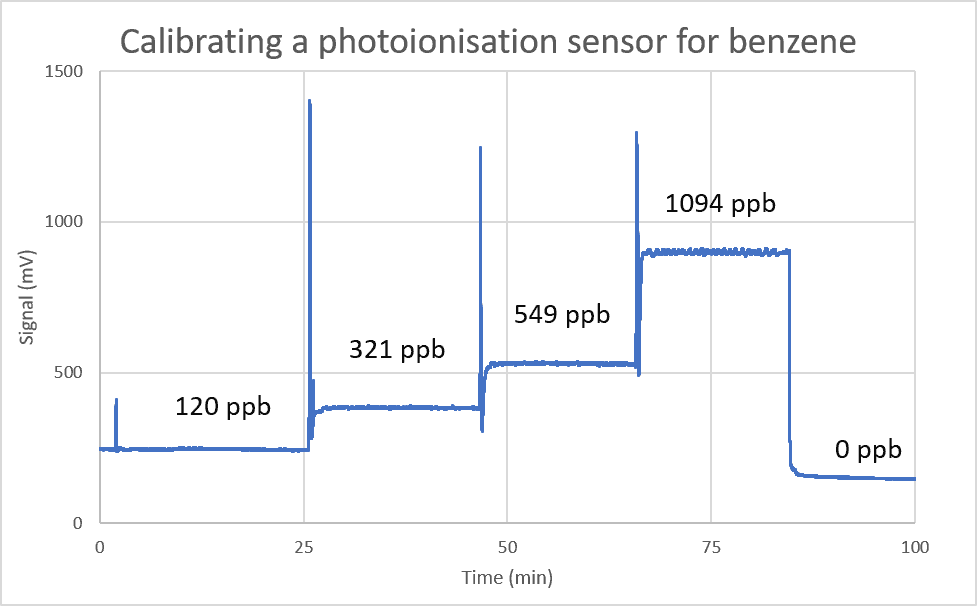

The device is designed to produce vapour streams with a predefined concentration of chemical compounds both in the lab and outdoors. Users simply insert a sealed permeation tube with the compound of choice into the designated compartment on the FemtoMachine, select the concentration level at the outlet and run the calibration method.

The T4i FemtoMachine® PRO is mainly used for calibrating chemical analysis instruments, detectors and sensors.

However, it can also be used for training in chemical detection. The company offers state-of-the-art and highly-customisable solutions through advanced design, miniaturisation and fast prototyping.

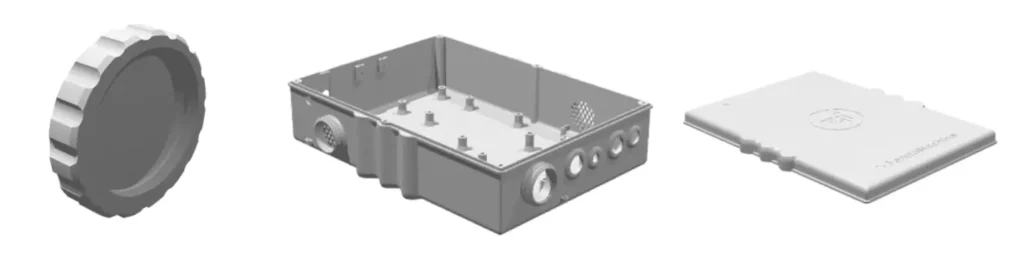

The Case is One of the Key Features of the Device

Despite the complexity and impressive functionality of the device, the case is actually a feature customers particularly value. “We didn’t expect the case to be a key feature of the device, but the customers thought otherwise,” explains Psarras. “It was a real innovation in terms of design—the devices that already exist on the market are square-shaped, bulky, white and kind of boring to the customers”.

The casing is a crucial component of the device so T4i Engineering paid particular attention to its ergonomics, aesthetics and design. With this in mind, Psarras decided to go for 3D printing to ensure maximum flexibility in terms of design, printing process and material.

The engineering team had made a few attempts in-house with their own FDM 3D printer, but they weren’t satisfied with the results. That’s why they called upon Xometry’s 3D printing services and used the Instant Quoting Engine, which gave them all the necessary information about materials, additive manufacturing processes, delivery time and cost.

By combining the online resources about 3D printing and post-processing on Xometry’s website and the instant quotes he got from the automated tool, Psarras concluded that SLS (Selective Laser Sintering) was the most cost-effective option. He selected PA 12, the most suitable material from the list of options, and a blue dye finishing option to meet his engineering and aesthetic requirements.

The Ease of Use of Xometry’s Instant Quoting Engine

“We really like the online analysis that provides you with an automated quote and manufacturability feedback,” states Psarras. He particularly enjoys the speed of the whole ordering process and being able to change the parameters to get instant quotes for different options. In the past, this process would have taken hours to manage on the phone or by email.

“We started using the Instant Quoting Engine about two years ago,” explains Psarras. “Now the interface looks better and it has more options in terms of processes and materials.”

A couple of years ago the company’s protocol meant that the engineers had to request quotes from different providers. Xometry’s attractive pricing stood out and T4i Engineering got them to manufacture a few parts. The cost-effectiveness and high-quality of the parts convinced them to source the majority of their mechanical components from Xometry.

Not only does Xometry produce the plastic 3D printed casing, but also metal custom parts that are critical for the device. These parts were manufactured with CNC machining in aluminium 6061 and stainless steel 316L due to strength, weight and chemical compatibility requirements.

In just a few clicks and for different manufacturing processes, engineers can upload multiple 3D models into one single quote and order the parts from the online platform. “What Xometry offers is the ease of evaluating the designs, getting feedback and prices on the fly,” states Psarras.

“I am more than satisfied with this automated tool. And in case I have a specific question or requirement, I can just send an email to Georgy Toskar, our Xometry account manager”.

Flawless Communication and Production Process

According to Psarras, Xometry’s strength also lies in the great communication between the customer and their sales and production contacts in the company.

Psarras uploaded the design of critical intricate parts that had specific manufacturing requirements. For example, separate components needed to be aligned in a very precise way when threaded together. In order to do so, the manufacturer had to be aware of these requirements.

The T4i engineer explained everything to Georgy Toskar and Alexander Kosotin (Production Manager at Xometry). “We just exchanged a few emails and in the end, the parts we received were correctly manufactured and could be assembled together,” reports Psarras. “I was personally very happy with the communication with Georgy, the support and the whole customer experience with Xometry.”

T4i Femtomachine® LCD: the Next Prototype on the Way

T4i Engineering is currently experimenting with a new version of the calibrator, which is now equipped with a screen and a keyboard. This allows the user to activate and launch the calibration method directly on the device without using a computer. You simply add the sealed permeation tube with the compound of choice, control the outlet concentration and connect it to the sensor you want to calibrate.

The company is also considering increasing the production volume for its calibrators. “In case we start producing the T4i FemtoMachine® in high volumes, we would probably go from SLS 3D printing to plastic injection moulding,” explains Psarras.

“Since we are still gathering feedback on the casing design of the new LCD version, we would rather keep producing the cases with 3D printing, until we are sure there won’t be any further tweaking needed,” he concludes. “But whether it’s 3D printing or plastic injection moulding, we will definitely source our parts with Xometry”.

More Information

About T4i Engineering

T4i Engineering provides products, solutions and services in the areas of field (on-site) chemical analysis, specialised electronics design and materials science.

More about T4i Engineering: https://www.t4ieng.com/about-us/

Contact T4i Engineering: info@t4ieng.com

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط